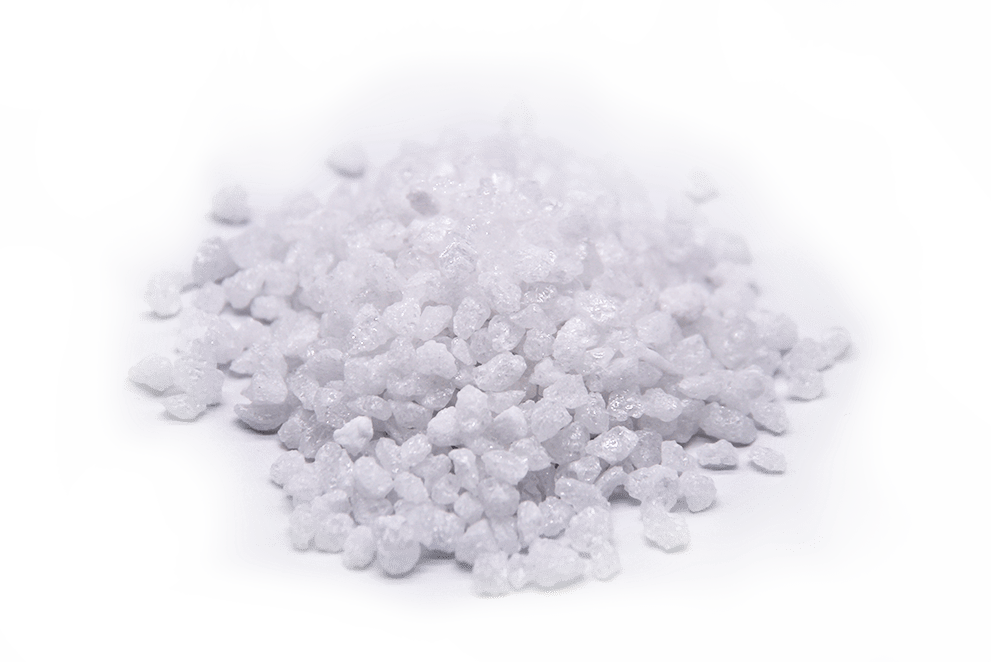

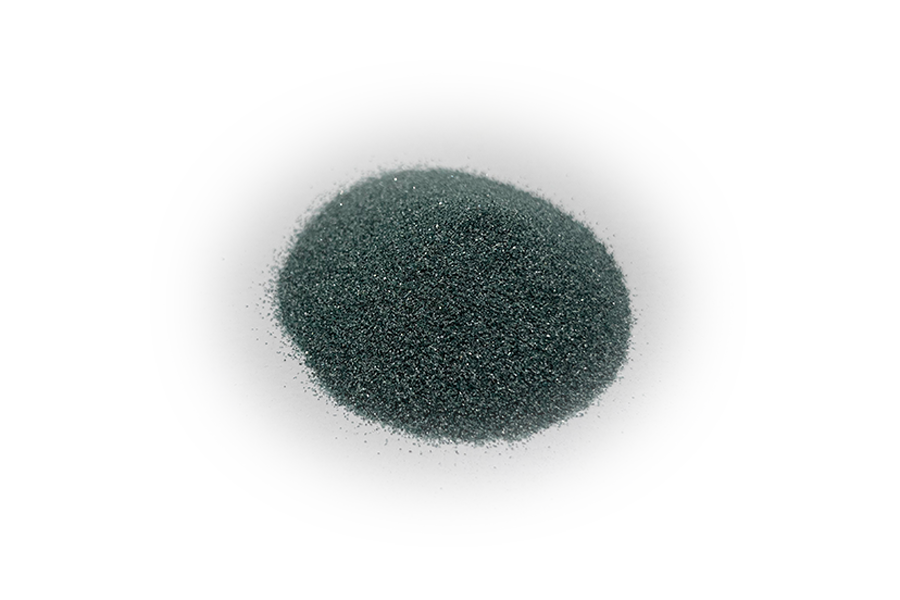

Low Na2o White Fused Alumina, Tiasa Dipaké Dina Refractory, Castables Jeung Abrasives

- Corundum bodas

- Alundum bodas

- WFA

Pedaran pondok

Komposisi kimiawi

| Barang | Unit | Indéks | has | ||

| Komposisi kimiawi | Al2O3 | % | 99.00 mnt | 99.5 | |

| SiO2 | % | 0,20 max | 0.08 | ||

| Fe2O3 | % | 0,10 max | 0.05 | ||

| Na2O | % | 0,40 max | 0.27 | ||

| Refractoriness | ℃ | 1850 mnt | |||

| Kapadetan bulk | g/cm3 | 3.50 mnt | |||

| Mohs karasa | --- | 9.00 mnt | |||

| Fase kristalin utama | --- | α-Al2O3 | |||

| Ukuran kristal: | μm | 600-1400 | |||

| Kapadetan leres | 3.90 mnt | ||||

| Teu karasa Knoop | Kg/mm2 | ||||

| Kelas Refractory | gandum | mm | 0-50,0-1, 1-3, 3-5,5-8 | ||

| bolong | -8+16,-16+30,-30+60,-60+90 | ||||

| Denda | bolong | -100,-200, -325 | |||

| Abrasive & Blasting Kelas | FEPA | F12-F220 | |||

| Polishing & grinding Kelas | FEPA | F240-F1200 | |||

Bodas ngahiji Varian alumina

| Produk / Spésifikasi | Al2O3 | SiO2 | Fe2O3 | Na2O |

| WFA Low Soda séréal jeung fines | >99.2 | <0.2 | <0.1 | <0.2 |

| WFA 98 Séréal jeung fines | >98 | <0.2 | <0.2 | <0.5 |

| WFA98% Demagnetized Denda -200, -325 jeung -500Mesh | >98 | <0.3 | <0.5 | <0.8 |

| Barang | Ukuran | Komposisi Kimia (%) | |

| Fe2O3 (mnt) | Na2O (maks) | ||

| WA & WA-P | F4~F80 P12~P80 | 99.10 | 0.35 |

| F90~F150 P100 ~ P150 | 98.10 | 0.4 | |

| F180~F220 P180 ~ P220 | 98.60 | 0.50 | |

| F230~F800 P240~P800 | 98.30 | 0.60 | |

| F1000~F1200 P1000~P1200 | 98.10 | 0.7 | |

| P1500~P2500 | 97.50 | 0.90 | |

| WA-B | F4~F80 | 99.00 | 0.50 |

| F90~F150 | 99.00 | 0.60 | |

| F180~F220 | 98.50 | 0.60 | |

Bahan Baku Jeung Prosés Produksi

White Fused Alumina mangrupakeun purity tinggi, mineral sintétik.

Hal ieu dijieun ku fusi kualitas dikawasa murni Bayer Alumina dina tungku busur listrik dina suhu leuwih gede ti 2000˚C dituturkeun ku prosés solidification slow.

Kontrol anu ketat pikeun kualitas bahan baku sareng parameter fusi mastikeun produk anu murni sareng keputihan anu luhur.

Atah nu leuwih tiis ieu salajengna ditumbuk, cleaned tina najis magnét dina inténsitas tinggi separators magnét sarta digolongkeun kana fraksi ukuran sempit pikeun nyocogkeun pamakéan tungtung.

Aplikasi

garis dedicated ngahasilkeun produk pikeun aplikasi béda.

Alumina Fused Bodas pisan rapuh sareng ku kituna dianggo dina produk Vitrified Bonded Abrasives dimana tindakan motong gancang sareng tiis penting sareng ogé dina pembuatan refraktori Alumina anu murni.Aplikasi sanésna kalebet dianggo dina Abrasive Dilapis, Perawatan Permukaan, Ubin Keramik, Cat Anti Skid, Tungku Fluidized sareng Perawatan Kulit / Dental.

Ngeunaan Produksi